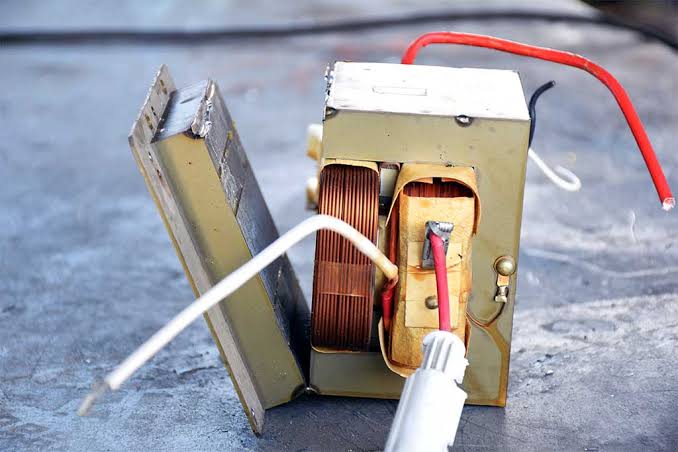

For example, this transformer is 'Stacked'. You can see the ' E ' shape stack that the Copper coils wound around the inside finger of the E.

The other ' I ' shaped stack, the closest side to you, you can see the faint line where they join, and the slight hollow on the outer of the

core on the faint line, where the weld is.

Bash that 'I' core on one end a few times, flip it over & bash the other end & it will start breaking off, untill its just the E & the Copper coils.

Punch the E out of the Coils.

Then, in this case theres varnished cardboard around the coil, cut thru it & peel as much off as possible.

Find out exactly what they would class this as, and its price. I would expect 'Copper Dom(estic)' but a year ago i would have got 'Copper #2' price.

My buyer might even say "Copper burnt'. Depending on what they are selling at the time.

This is a very good photo of a

Microwave oven transformer partly split open at the join, if you use a angle grinder, you can partly grind a groove 8nto that weld to weaken it and the I core won't break apart ( some might still ) when the I stacks removed from the E stack.

Microwave oven coils are normally about 900 gms, so 2 Lbs.

But, later model microwave transformers are very often one Copper coil, & one Aluminium coil.

Even worse, some have 2 Aluminium coils.

Its easy to figure out beforehand by scraping a 3xpos3d part of the coil with a knife, screwdriver, or preferred, a file. If its a lighter reddish Copper where you exposed the inner of the wire. Its Copper.

If its White or Silvery, its Aluminium.

It would pay to check first, but i would not expect there to be any Aluminium coils in lighting transformers.

~~~~~~~~~~~~

This transformer is interesting, its not common, but its the easyest version to work with.

Its simply a Stacked outer core, with a Stacked Inner core, thats got the Copper coils on it.

Use maybe a Hydraulic press to press the inner Iron core laminations & coil out in one piece.

I would use my 'Thor' like heavy short handled hammer & my bench vise.

Thats definatly some good workout for your biceps. Well one at least.

Then punch the Iron ' I ' shaped core out of the Copper coils.

Its the same insulation as above.

300 transformers? !!! Thats about NZ$1800 worth of Copper. Maybe round down to NZ$1500, thats US$1000.

Do break one open, clean & weigh the Copper ( check that they are Copper ) coils, use something accurate to a few grams.

Post your results please.

You wont be able to post photos untill you have made something like 7 or 8 posts.

Register To Reply

Register To Reply

Bookmarks