Just a little something about the puzzles you'll face.

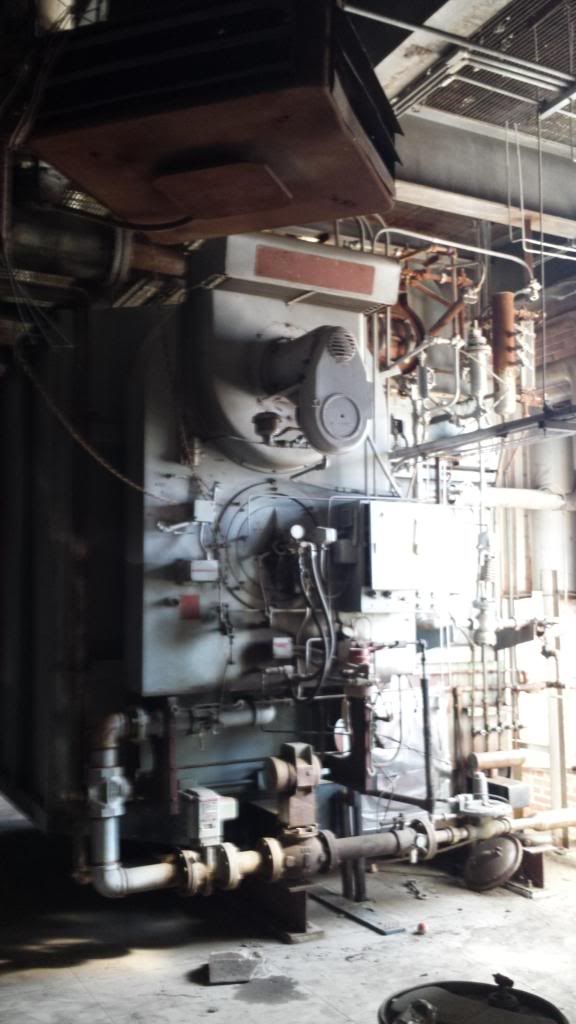

Construction and demolition are near identical, although maybe in reverse order.

I just wanted to tell you my trick for sorting things out, although it may be already well known to you. In case it isn't, I'd like to offer it to you now.

Something like the job you've been given, maybe you have the plans, maybe they've made the charts for time frames, but you'll still have unknowns, maybe multiples in your case. You have a lot to deal with there I know.

I'm just talking about simple basics, and not getting lost. Somebody dumps a truckload of bolts and beams in your yard with no instructions, what do you do? Where do you start?

Simply sort it out, and take the parts you do know(that's my whole point here, the parts you do know or can figure), when you get those ones sorted out, the unknowns will most times sort themselves, and fit right in (or fall into place, as the case may be)

Something else just came to mind(not wanting to change the subject, or distract from my intended point) but there's a lot of weight up there, which you'll be cutting. There is a lot of energy stored in that dead weight, it is ruled by gravity. As you release that weight from it's moorings, gravity will turn it into energy, until it finds it's next resting place(safely, we hope). I'll liken it to felling a large tree for firewood. After it's found its resting place on the ground, there is still immense energy stored in every limb, and as you whittle each limb it releases the energy slowly. You build up blocking under the trunk to support it from underneath as you whittle away the weight(energy) from above, in small slices. By the time you get to the immense trunk, although it's much heavier than the energy laden limbs once above it, it has very little energy left, and can be more easily and safely cut and removed.

You'll have a lot of puzzles to solve, start with what you know; and a lot of energy to release, bring it down safely; and a lot of things to think about, don't let me distract you : )

Register To Reply

Register To Reply

-

-

Bookmarks