This is the other boiler before any cuts are made.

This is the first layers of pipe cut. The torch men walked to the end of the row of steam pipe, cutting it as the moved back and let it drop to the basement.

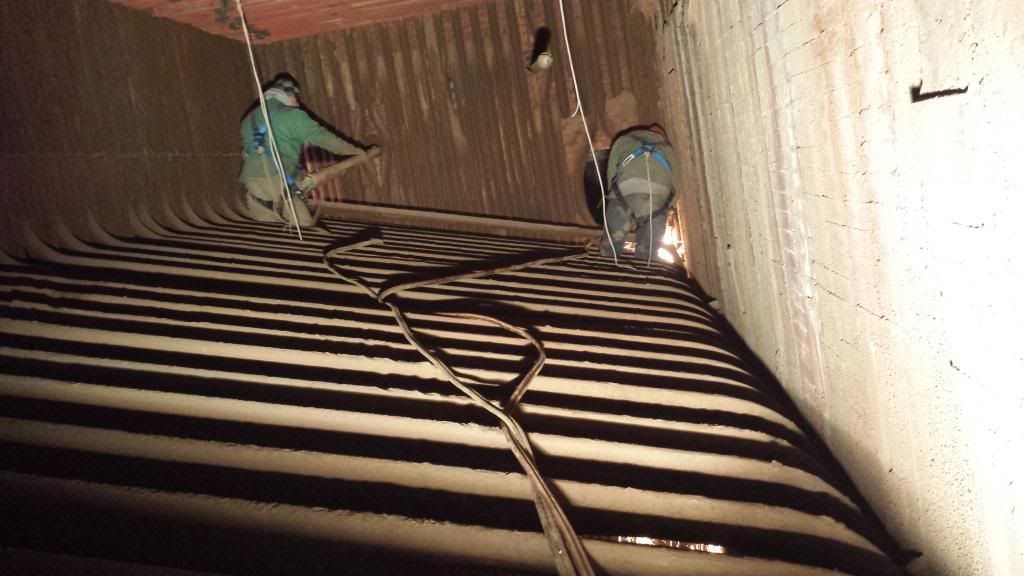

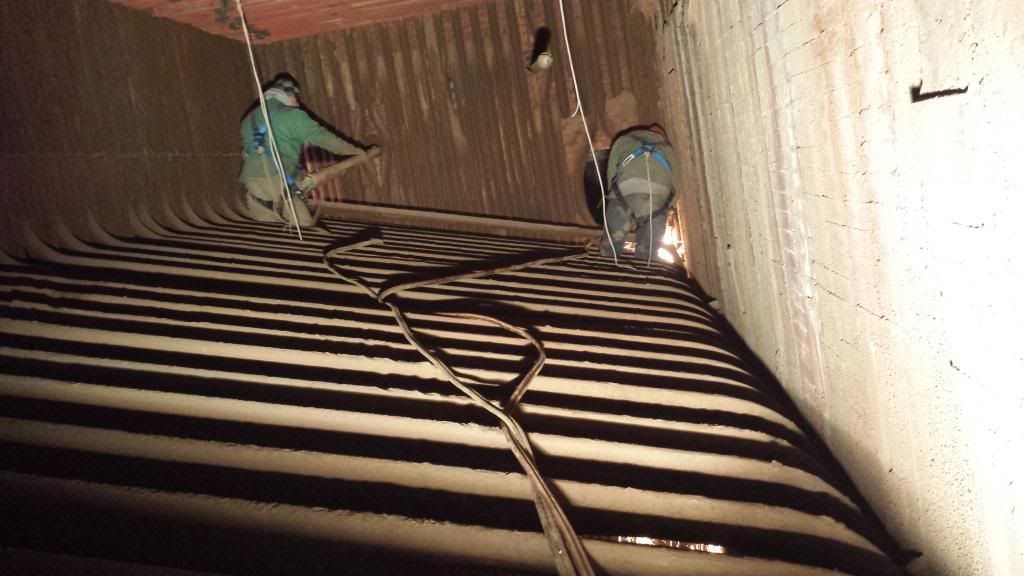

A picture of workers cutting the steam pipe three floors up. They are cutting upper layers of pipe as they stand on the lower layers. When they get to the end they will cut what they have been standing on as they work there way back to the openings. The pipe drops to the basement level inside the boiler to be picked up by skid loaders and taken to the pit to be pulled out by the excavator with a thumb bucket.

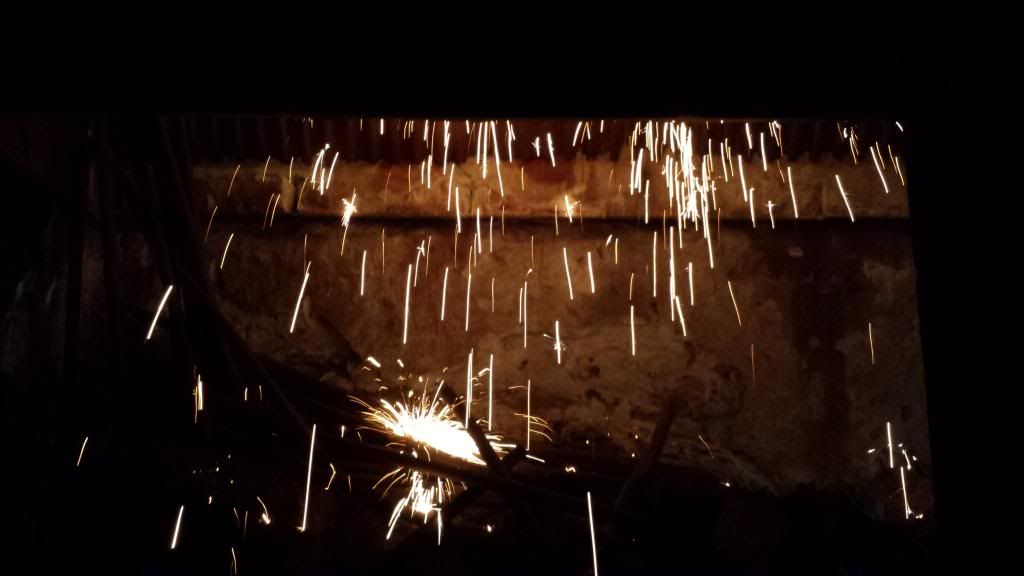

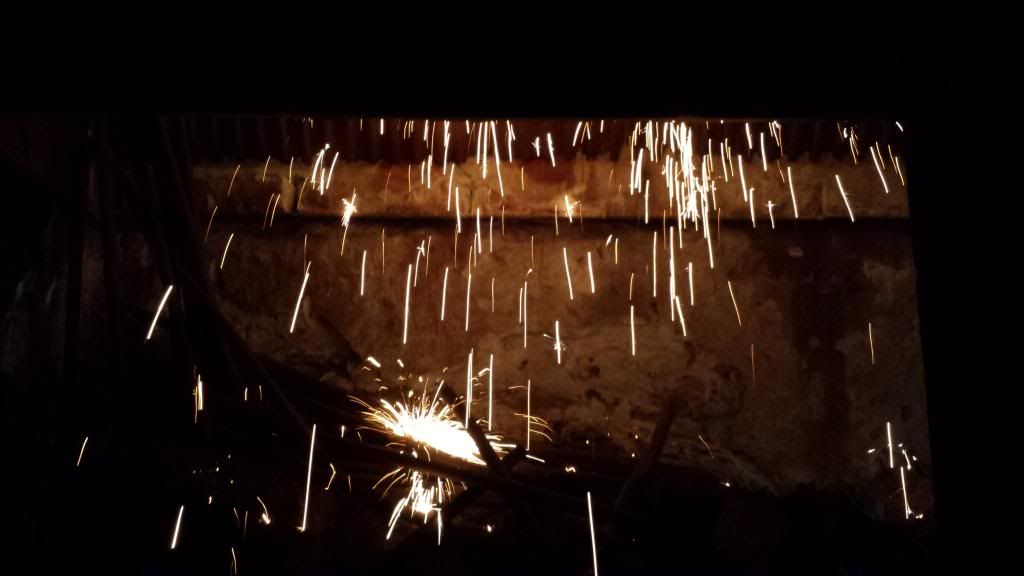

A couple of pictures of the sparks falling three floors into the bottom of the boiler. The first one is looking at the bottom of the steam pipe they are standing on and cutting and the second one is the bottom of the boiler before the log jam in the next post.

Bookmarks