When the unit is running some oil travels along with the freon, the oil become saturated with oil in the same way your soda pop has carbon dioxide to give it the fizz. Let an open bottle or glass of pop sit for a day or so it becomes flat.

To completely evacuate a unit it should be drawn down into a vacuum, to turn the remaining freon into vapour by boiling yes that is correct boiling. By introducing a vacuum into the system we are lowering the boiling temperature of freon turning it into a vapour which the recovery unit turns back into a liquid as the freon is being pumped into a receiver used to ship the recovered freon to a recycler.

Sometimes a refrigeration or AC unit becomes wet with water contamination, on commercial units which are equipped with a sight glass the green dot in the middle will change colour if there is water present. Water freezes causing an ice ball to form where the freon is exiting from the capillary tube or sporlan valve intio the evaporator. The ice ball prevents the flow of freon which caurses the unit to build up an excess of pressure possibly damaging the compressor if your lucky just stop cooling of go into a loop where the over load continually tries to start the compressor which will not start as long as the ice ball is blocking the system from passing freon as a gas.

Ok, now to remove this water we have to first evacuate the system of freon once this is accomplished we now put a vacuum pump to the shrader valve we initially installed to evacuate the system. This vacuum pump is made especially for this job and will pull a vacuum into the microns, now were going to get more freon then any water in the system is going to also boil off as a vapour.

Good time to replace the compressor oil as the water mixed with the oil and freon created acids that are harmful to the motors insulation, that done we install a new filter drier then replace the freon with new.

If we were to pump liquid freon out of the unit we would stand a chance of hydraulicing the piston causing the recovery pump to lock up, break a connecting rod or damage the reed valves.

Evacuating a unit is time consuming so most guys will tap into the high side removing liquid freon, to do this the compressor on the unit being evacuated must run in order to make liquid, once there is no more liquid freon coming out the technician signs off the job and goes home leaving saturated oil inside the compressor but saved 3/4 of an hour and gets paid the same money had he put in the time to do a proper job.

You wont find many refrigeration technicians claiming to enjoy this part of the job and this is perhaps a good reason for many a scrapper to approach a licensed tech to work as an apprentice. If you were competent at your work I do not believe the technician would have to be present to oversee your work he might have to sign off though so marshalling all your units into one easy location would make that part of his requirement easy.

AC units usually use multiple capillary tubes, liquid freon from the high side makes it way through the tubes which unite at the evaporator, the liquid freon as it leaves the cap tubes become a gas that absorbs heat. To us humans the air passing over the evaporator coil is cool and refreshing.

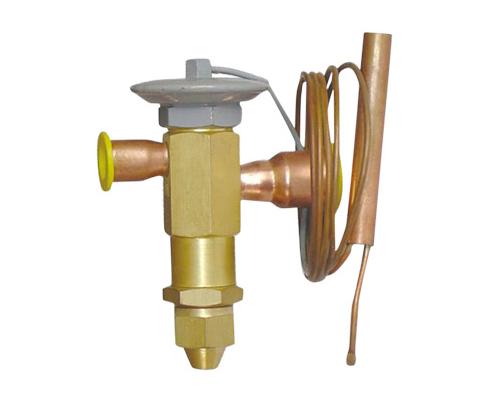

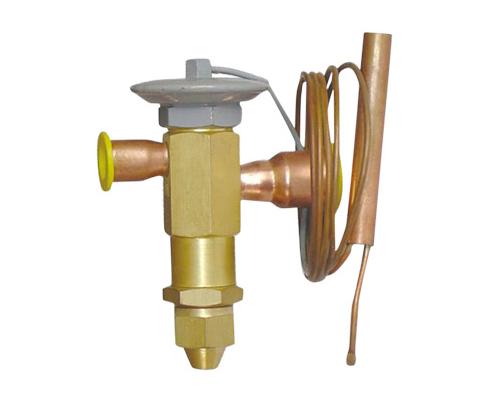

Large commercial units use a sporlan valve which are pretty cool valves that have a needle valve inside the technician is able to make adjustments that control the flow of liquid being turned into a gas. The more freon available to turn into gas make it a cooler or walk in freezer.

On the bottom of the sporlan valve below you see a cap screw, you remove the cap screw to make the adjustments. The copper line attached to the top of the valve is what controls a bellow that works the needle valve. By turning the adjustment screw in your adding more pressure to the spring which in turn cuts down on the flow of freon if you want the box to be colder back the screw out thus allowing more freon to pass through the system.

Register To Reply

Register To Reply

-

-

Bookmarks